| |

|

|

Type and Specifications of the Auto Machine Welder |

| |

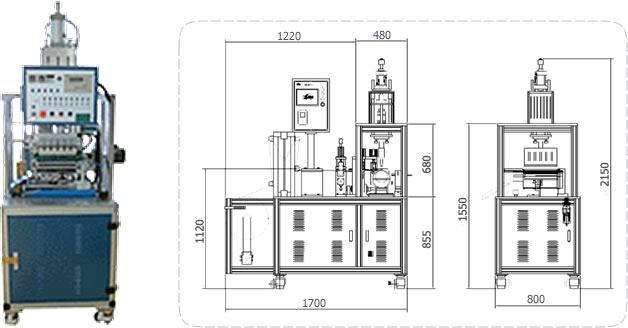

01. PVC cylinder welder 01. PVC cylinder welder |

| |

|

| |

|

● Feature

| |

|

Good durability as advanced circuit |

| |

|

Easy to operate, even for beginners, easily operation |

| |

|

Mold batch production and exchange (60Φ~150Φ) |

| |

|

PLC control system and servo control system |

| |

|

Touch screen method |

| |

|

Can be produced by way to move the Table |

|

|

| |

|

| |

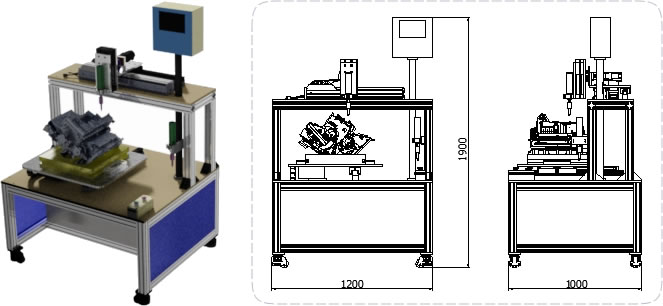

02. Orthogonal robot welder 02. Orthogonal robot welder |

| |

|

| |

|

● Feature

| |

|

Program want to change the left, right, up, down, angle can be adjusted |

| |

|

Ultrasonic for excellent adhesion (30kHz) |

| |

|

Easy to operate, even for beginners, easily operation |

| |

|

Suitable for staking, swaging, inserting, spot welding |

| |

|

PLC type and server control system |

| |

|

Touch screen method |

| |

|

Can be produced by way to move the Table |

|

|

| |

|

| |

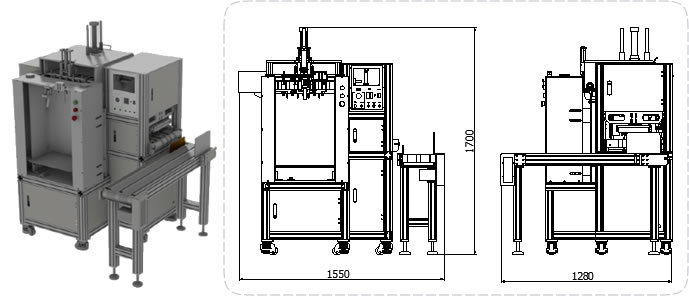

03. L-Holder Auto 03. L-Holder Auto |

| |

|

| |

|

● Feature

| |

|

Operation is easy, even for beginners anyone can be produced easily |

| |

|

Automatic welding supply entry to the automatic production |

| |

|

Minute 30EA or production hour over 18000EA |

| |

|

Excellent adhesion for the work surface clean (Ultrasonic frequency 20kHz Mounting) |

| |

|

Carrying capacity of approximately 2000EA |

| |

|

PCL control method |

| |

|

Touch screen method |

|

|

| |

|

| |

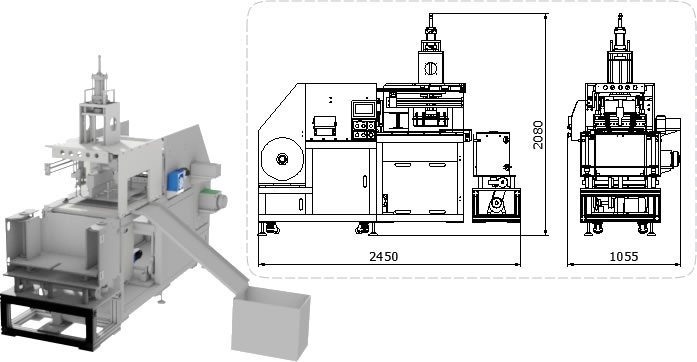

04. 10P파일 자동 04. 10P파일 자동 |

| |

|

| |

|

● Feature

| |

|

Easy to operate, even for beginners, anyone can be produced easily |

| |

|

Can be produced by freely setting inside files 5-10P by selecting |

| |

|

Clean the work surface for excellent adhesion |

| |

|

Inside Paper Auto Supply |

| |

|

Cover Auto Supply |

| |

|

PLC control system |

| |

|

Touch screen method |

|

|

| |

|

| |

05. Roll L-Holder Auto 05. Roll L-Holder Auto |

| |

|

| |

|

● Feature

| |

|

Easy to operate, even for beginners, anyone can be produced easily |

| |

|

There is no hassle of moving and working twice a built-in gold flicks |

| |

|

Excellent adhesion for the work surface clean (Ultrasonic frequency 20kHz Mounting) |

| |

|

Roll Auto Supply |

| |

|

PLC control system |

| |

|

Touch screen method |

|

|

| |

|

| |

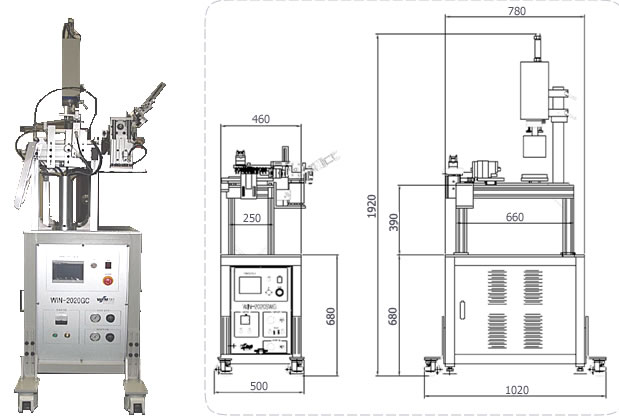

06. WIN-2020GC 06. WIN-2020GC |

| |

|

| |

● Specifications

| Model |

WIN-2020GC |

| Output |

2000 W |

| Power Supply |

AC220V 50/60Hz |

| Frequency |

20 KHz |

| Current |

15 A |

| Size

(WxLxH) |

500 x 1020 x 1920 mm |

| Welding Time |

0.01 ~ 9.9 sec |

| Max. Stroke |

75 mm |

| Oscillator |

BLT |

| Cooling Method |

Air-cooled |

| HORN/JIG |

Specially designed |

|

● Feature

| |

|

Product entry automatically in conjunction with the injection molding machine |

| |

|

Product entry that is fast and clean |

| |

|

PLC control system |

| |

|

Using the touch screen |

| |

|

Easy one-touch operation Air Press |

| |

|

Precision Products jobs in good precision timer. |

| |

|

Leveling device is equipped with settings easily adjustable. |

| |

|

Easy to work the way you move Move Table . |

| |

|

The built-in counter which can check the operation quantity |

| |

|

With precise strokes. |

| |

|

Freely adjustable head height. |

|

|

| |

|