|

Overview of the hot plate welder |

| |

Fixed to the jig up and down for the complex is heated to a temperature slightly higher

than the melting temperature of the material.To solidify by cooling until the weld when

the weld area is fully melted, remove the plates and cross-pressurized after forming |

|

Long welding time but the disadvantages of the initial equipment cost is expensive

compared to other welding methods for complex

Large (up to for complexes: plastic

paelreot, to 1400 ¥ª 1100 mm), welding seam is curved and complex products

(Analgesic automotive lamps speakers balls, etc.), if the absolute welding method |

|

|

Diverse range of industrial applications such as automotive, electronics, packaging,

medical equipment, office containers, sports and leisure goods, hot plate welding process

is applied in the automotive industry, especially in the growing trend. Example), fuel filter,

fuel tank, float, rechargeable battery, radiator expansion tank, bumpers, power steering

tanks, etc. |

|

|

| |

|

|

Type and Specifications of the hot plate welder |

| |

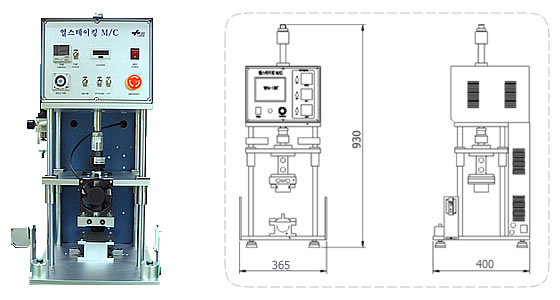

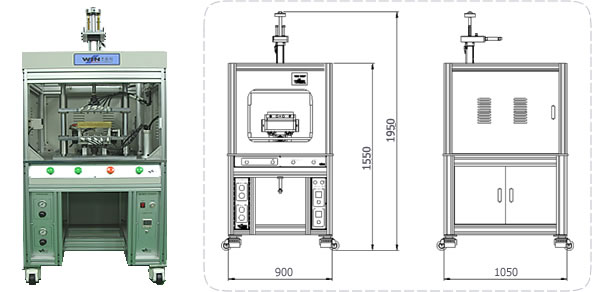

01. WINH-1INT 01. WINH-1INT |

| |

|

| |

|

¡Ü Feature

| |

|

One-side welding machine. |

| |

|

Fusion Intenna running up and down the side. |

| |

|

With precision thermostat to maintain the temperature. |

| |

|

Maintain a robust, accurate and durable

|

|

|

| |

|

| |

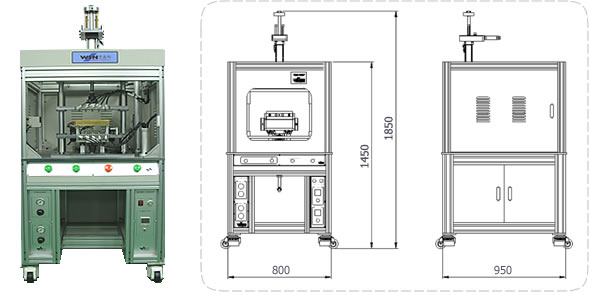

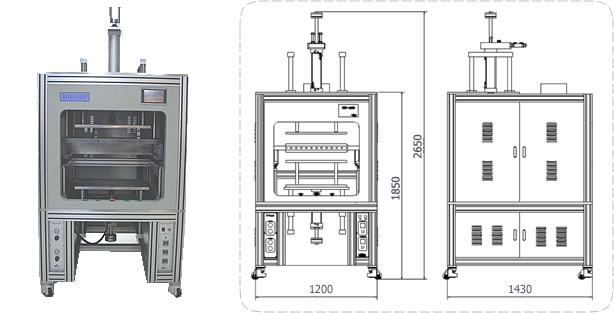

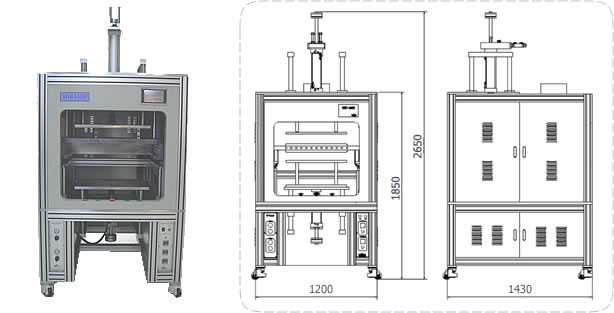

02. WINH-3INT 02. WINH-3INT |

| |

|

| |

|

¡Ü Feature

| |

|

Welding machine on three sides. |

| |

|

The fusion Intenna three sides, Left / Right, Up / Down.� |

| |

|

With precision thermostat to maintain the temperature. |

| |

|

Maintain a robust, accurate and durable |

|

|

| |

|

| |

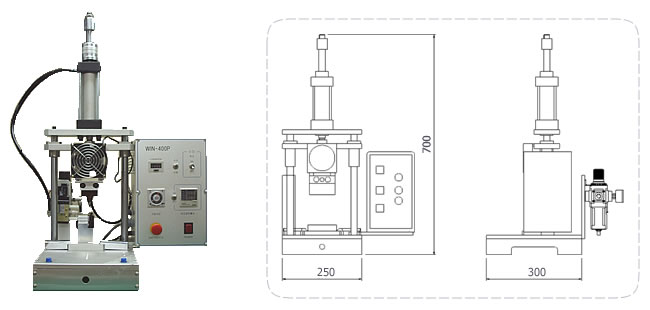

03. WINH-400P 03. WINH-400P |

| |

|

| |

|

¡Ü Feature

| |

|

Easy to weld staking inserts, the insertion of small products. |

| |

|

Running up and down the welding. |

| |

|

With precision thermostat to maintain the temperature. |

| |

|

Maintain a robust, accurate and durable |

|

|

| |

|

| |

04. WINH-1000P 04. WINH-1000P |

| |

|

| |

|

¡Ü Feature

|

|

| |

|

| |

05. WINH-2000P 05. WINH-2000P |

| |

|

| |

|

¡Ü Feature

|

|

| |

|

| |

06. WINH-3000P 06. WINH-3000P |

| |

|

| |

|

¡Ü Feature

|

|

| |

|

| |

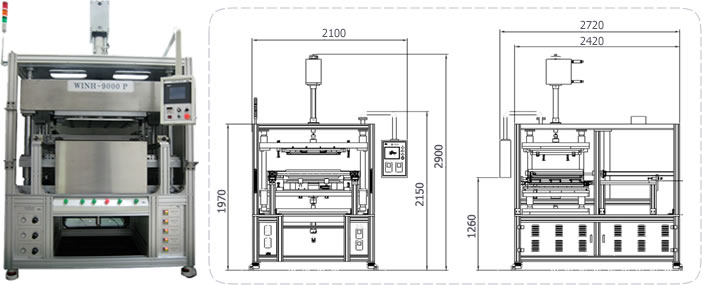

07. WINH-5000P 07. WINH-5000P |

| |

|

| |

|

¡Ü Feature

|

|

| |

|

| |

08. WINH-7000P 08. WINH-7000P |

| |

|

| |

|

¡Ü Feature

|

|

| |

|

| |

09. WINH-9000P 09. WINH-9000P |

| |

|

| |

|

¡Ü Feature

|

|

| |

|

| |

10. Made to Order 10. Made to Order |

| |

|

| |

|

|

|

| |

|